As a customized solar panels solution provider and high efficiency solar panel manufacturer, we work closely with our clients from the initial stage of product development, to providing technical support and optimized solar panel design options,

and meeting the specific needs of each and every one of our individual clients.

Our 5-Step Customized Solar Panel Development Process

Step 1: Client Consultation

Discuss the specific details of the required solar panel, e.g., size, voltage, solar cell type, power, materials, etc.

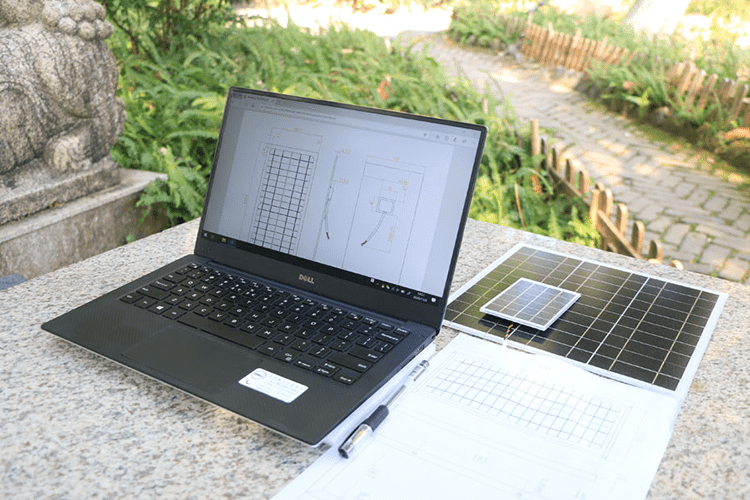

Step 2: Drawing

Based on the details discussed above, our experienced engineers will provide drawings and optimized solar panel design options tailored to your specific needs.

Step 3: Quotation

After the final drawings and design options are agreed, we will provide you with the most competitive price quotation available.

Step 4: Samples

After committing to your order, we will provide samples to meet your specific testing needs.

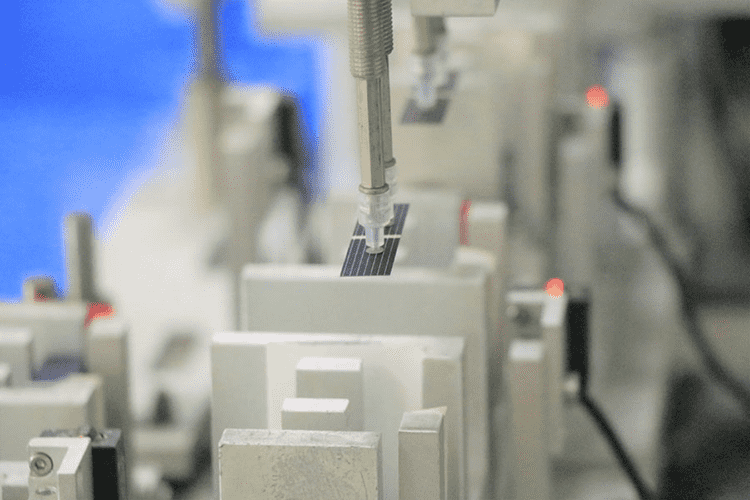

Step 5: Customized Production

Once the sample passes the test successfully, we will enter the customized production stage.

We wil determine:

The delivery date based on the client's spcific order quantity.

Prepare the materials and control every detail of the production process to ensure we meet your desired product quality.

We will perform 100% appearance and power inspection on all solar panels before shipment.

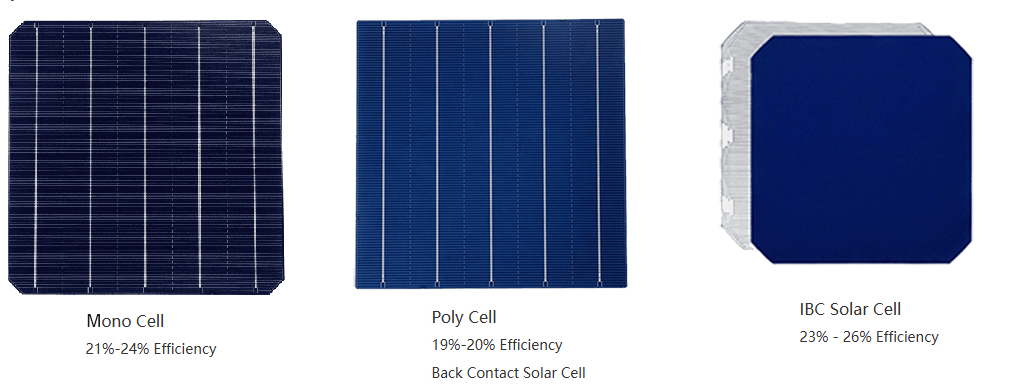

Commonly Used Solar Cell Types:

Solar cells can absorb sunlight and convert solar energy into electricity. They constitute the core component of the solar panel. The efficiency of solar cells determines the output power of the solar panel. For solar panels of the same size, the panel incorporating the highest efficiency solar cells will be the one that produces the highest power output.

The following are some of our commonly used solar cells.

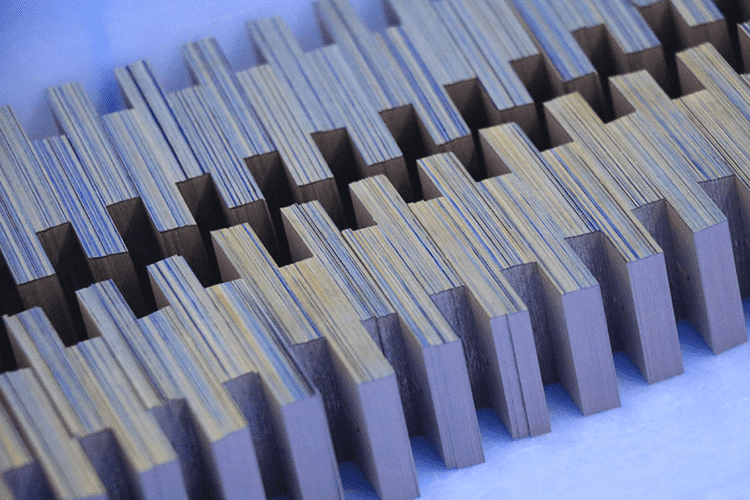

Crystalline Silicon Solar Cell

Usually we have to decide which type of solar cell to choose according to the client's requirements for solar panel size, cost considerations, and service life.

Crystalline silicon solar cells are currently the most widely used solar cells. They can be divided into monocrystalline silicon and polycrystalline silicon. Among them, the efficiency of monocrystalline silicon is higher than that of polycrystalline silicon, but the cost is slightly higher. Common encapsulation methods include glass lamination and PET lamination.

The efficiency of back contact solar cells is higher than that of ordinary crystalline silicon cells, but its cost is also higher. If you want to achieve the highest power in a compact size, you should consider using it. The common encapsulation method is usually ETFE or PET.

In short, from the perspective of efficiency, back contact solar cell efficiency (23% Efficiency), higher than both the mono solar cell (19.8%-22.5% Efficiency) & the poly solar cell (18.6%-19% Efficiency).

From the perspective of cost, back contact solar cells cost more than both mono solar cells & poly solar cells, and mono solar cells cost more than poly solar cells.

Monocrystalline silicon solar cells are usually the most widely used because of their cost effectiveness and high output efficiency.

How to Choose the Encapsulation Method

Encapsulation is a key step in the production of solar panels. The encapsulation of solar panels can not only ensure the life of the solar cells, but also enhance the resistance strength of the solar cells.

Our commonly used encapsulation methods are glass lamination, ETFE lamination or PET lamination

The difference between different encapsulation methods of solar panels

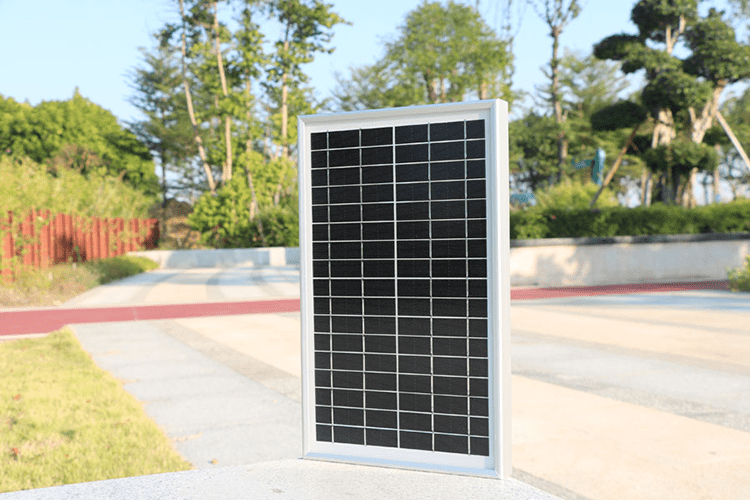

Glass Solar Panels:

Glass solar panels are durable, waterproof, UV resistant, not easy to scratch, and can be used in extreme conditions. They offer the longest life span which can stretch to at least 10 years. They are heavier than ETFE or PET panels and the thickness of the frameless glass solar panel is around 4.5 mm.

The structure is: glass/EVA/solar cell/EVA/back sheet. Glass solar panels are the most widely used.

ETFE Solar Panels:

ETFE solar panels are thin, light in weight, waterproof and UV resistant. Their life span can stretch to more than 5 years. Their thickness is around 2mm.

Their structure is: ETFE film/EVA/solar cell/EVA/PCB board.

PET Solar Panels:

PET solar panels are thin, light in weight, waterproof and UV resistant. Their life span is short and can only stretch to around 2 years. Their structure is: PET film/EVA/solar cell/EVA/PCB board. Due to its short lifespan

N.B. Due to their short lifespan, if the solar panel product application is for outdoor use, we usually do not recommend the deployment of PET solar panels.